2022 China New Design 2mm Mild Steel Plate - Theoretical Knowledge of Galvanized Steel Sheet – XINXIN PENGYUAN

2022 China New Design 2mm Mild Steel Plate - Theoretical Knowledge of Galvanized Steel Sheet – XINXIN PENGYUAN Detail:

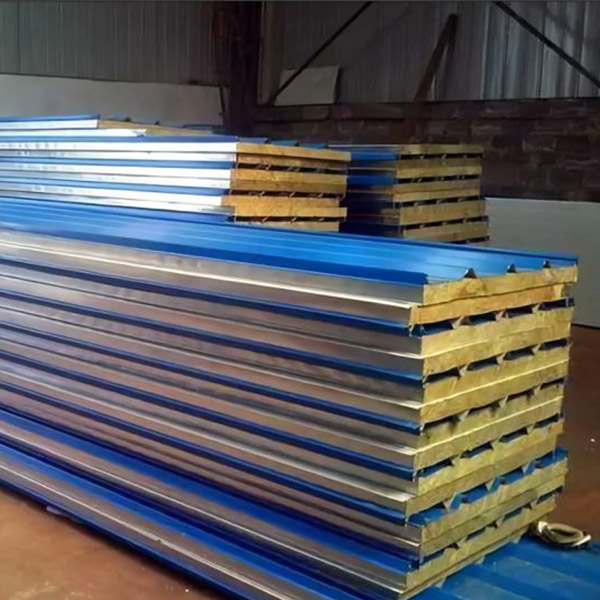

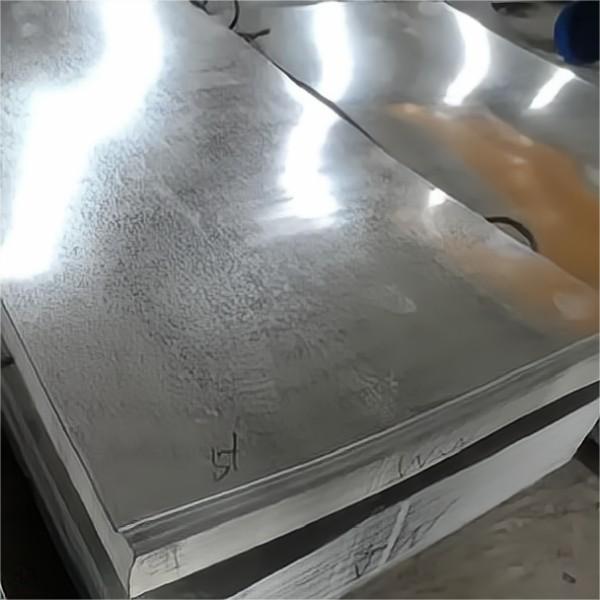

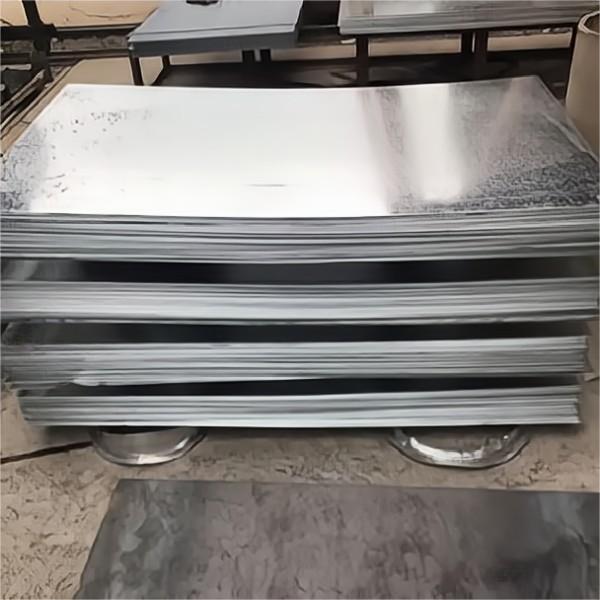

Hot dip galvanized steel strip has always been a scarce variety in China’s market. Since the mid-1990s, about 800000-1million tons have been imported from abroad every year. With the development of domestic economy, especially the development of automobile, home appliance and construction industry, the demand for galvanized strip steel has also increased greatly. China has built a batch of production lines with an annual output of more than 100000 tons in recent 20 years, but the hot-dip galvanizing units with low-level traditional technology in terms of process flow, equipment composition and product varieties can not meet the needs of China’s economic construction and development in terms of variety, quality and quantity, and new hot-dip galvanizing lines still need to be built to meet the needs of the market.

Since the 1990s, the production of galvanized steel sheet in China has made great progress, and the processing capacity of galvanized steel sheet in China has reached nearly 3million tons. The market share of domestic galvanized sheet has increased rapidly, from about 27% in 1996 to about 59% in 1998. The main domestic manufacturers are Baosteel, Wuhan Iron and steel, Panzhihua Iron and steel, Handan Iron and steel, Benxi Iron and steel, with a total production capacity of more than 1.3 million tons.

The main gap between the existing hot-dip galvanizing units in China and the foreign level lies in that the vast majority of units do not have pre cleaning equipment, so it is difficult to guarantee the surface quality of galvanizing; The existing finishing machines are relatively simple two roll finishing machines (Pangang has four rolls), which can not better improve the mechanical properties of the strip steel, especially the deep drawing performance; The existing varieties are all single galvanized plates, with only a small amount of alloyed plates, which is far from meeting the needs of the market.

The hot-dip galvanized steel plates produced by Chinese manufacturers are mainly used in building materials, light industry, agriculture, transportation and other industries. Due to the limitations of existing hot-dip galvanizing equipment conditions, process technology and raw plate performance, there are few galvanized plates that can be used in automobile manufacturing industry.

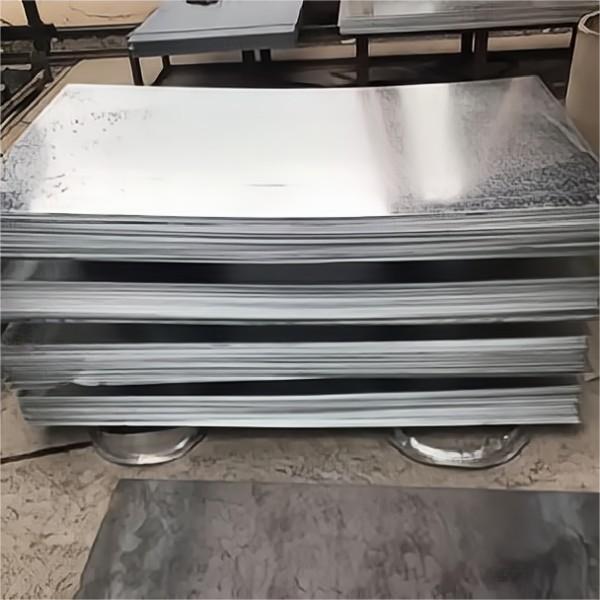

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for 2022 China New Design 2mm Mild Steel Plate - Theoretical Knowledge of Galvanized Steel Sheet – XINXIN PENGYUAN , The product will supply to all over the world, such as: Poland, Florence, United States, With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.