Best Quality Cold Rolled Galvanized Steel Coil - SAE1010 steel coil Black steel coil S235JR steel coilSummary of Theoretical Knowledge of Galvanized Coil – XINXIN PENGYUAN

Best Quality Cold Rolled Galvanized Steel Coil - SAE1010 steel coil Black steel coil S235JR steel coilSummary of Theoretical Knowledge of Galvanized Coil – XINXIN PENGYUAN Detail:

Defects mainly include: falling off, scratches, passivation spots, zinc particles, thick edges, air knife stripes, air knife scratches, exposed steel, inclusions, mechanical damage, poor performance of steel base, wavy edges, ladles, improper size, embossing, improper thickness of zinc layer, roller printing, etc.

The main reasons for zinc layer falling off are: surface oxidation, silicon compounds, too dirty cold rolling emulsion, too high oxidation atmosphere in NOF section and dew point of protective gas, unreasonable air-fuel ratio, low hydrogen flow, oxygen infiltration in the furnace, low temperature of strip steel entering the pot, low furnace pressure in RWP section and air suction in furnace door, low furnace temperature in NOF section, endless oil evaporation, low aluminum content in zinc pot, too fast unit speed, insufficient reduction, too short residence time in zinc liquid The coating is too thick.

The causes of white rust and black spots are: black spots are formed by the further oxidation of white rust.

The main causes of white rust are:

(1) Poor passivation, insufficient or uneven passivation film thickness;

(2) The surface is not oiled or there is residual water on the surface of the strip steel;

(3) There is moisture on the surface of strip steel during coiling;

(4) Passivation is not completely dried;

(5) Damp or rain during transportation or storage;

(6) The storage time of finished products is too long;

(7) The galvanized sheet is in contact with or stored with other corrosive media such as acid and alkali.

The finished products can be stored in the warehouse for up to three months to avoid oxidation.

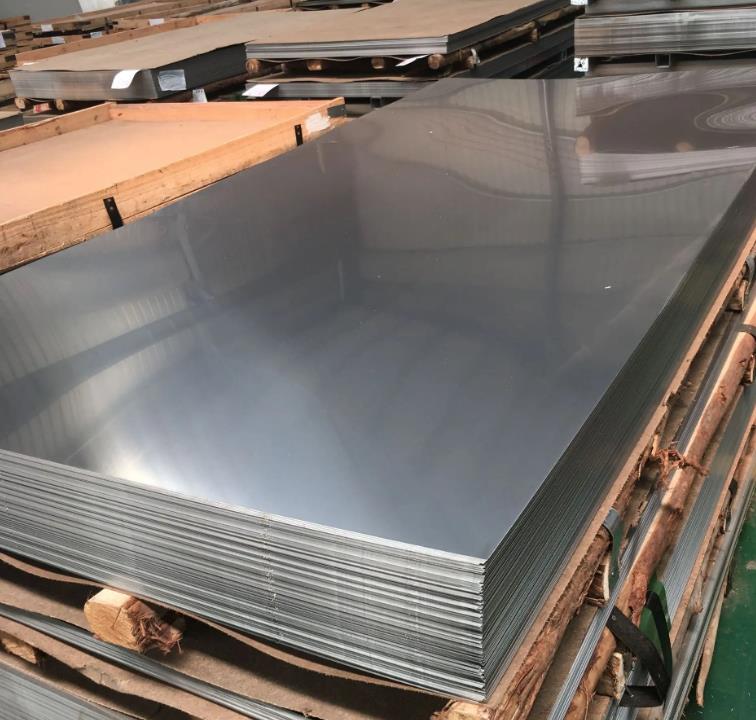

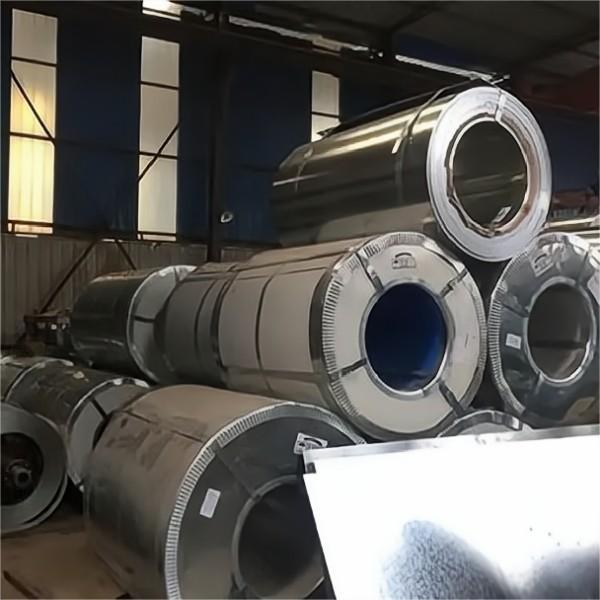

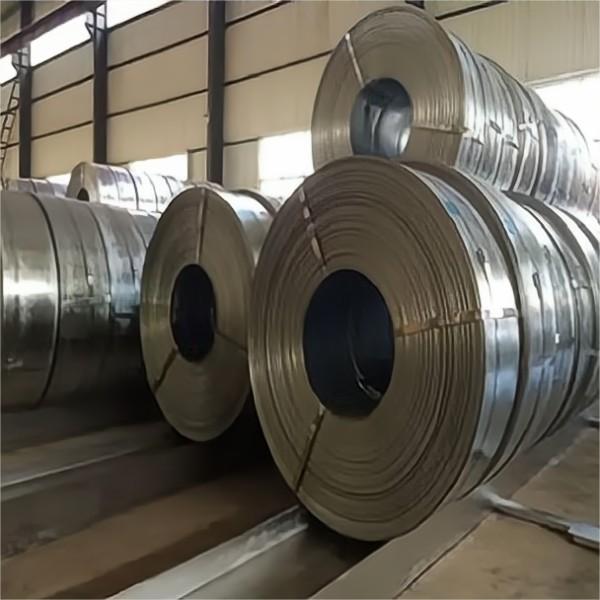

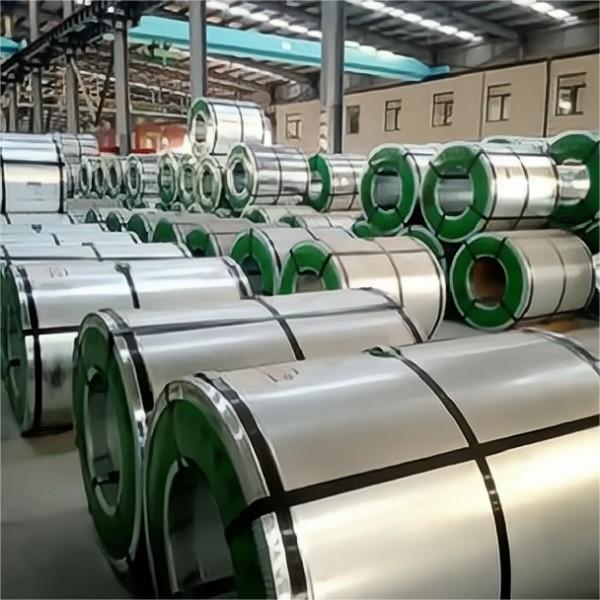

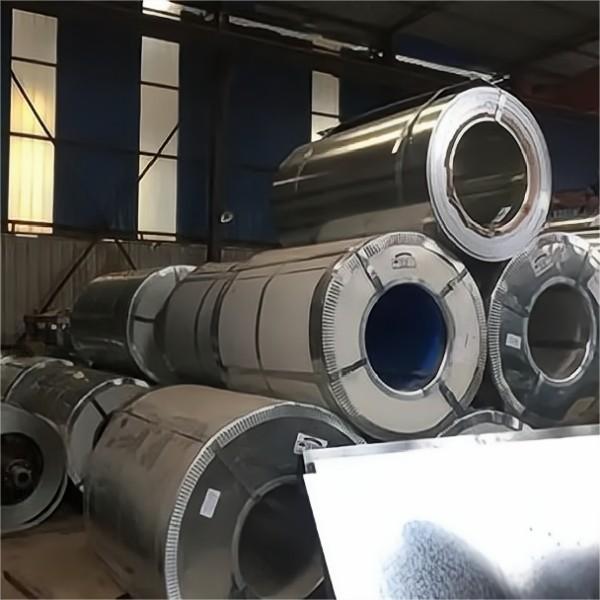

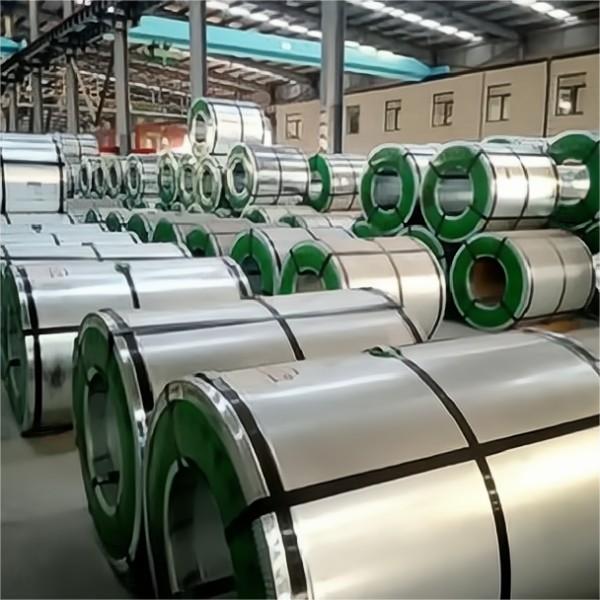

Product detail pictures:

Related Product Guide:

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for Best Quality Cold Rolled Galvanized Steel Coil - SAE1010 steel coil Black steel coil S235JR steel coilSummary of Theoretical Knowledge of Galvanized Coil – XINXIN PENGYUAN , The product will supply to all over the world, such as: Irish, Guinea, Karachi, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.