Special Design For NM 450 Steel Plate - Theoretical Knowledge of Wear-Resistant Steel Plate – XINXIN PENGYUAN

Special Design For NM 450 Steel Plate - Theoretical Knowledge of Wear-Resistant Steel Plate – XINXIN PENGYUAN Detail:

The wear-resistant layer of the alloy is mainly chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are also added. The carbides in the metallographic structure are fibrous distribution, and the fiber direction is perpendicular to the surface. The micro hardness of carbide can reach above hv1700-2000, and the surface hardness can reach HRC58-62. Alloy carbides have strong stability at high temperature, maintain high hardness, and have good oxidation resistance. They can be used normally under 500 ℃.

The wear-resistant layer has narrow channels (2.5-3.5mm), wide channels (8-12mm), curves (s, w), etc; It is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium, nickel and boron are also added. The carbides in the metallographic structure are distributed in fibrous form, and the fiber direction is perpendicular to the surface. The carbide content is 40-60%, the microhardness can reach above hv1700, and the surface hardness can reach HRC58-62.

The wear-resistant steel plate alloy wear-resistant layer and the substrate are metallurgically bonded. Through special equipment and automatic welding process, the high hardness self protective alloy welding wire is uniformly welded on the substrate, and the composite layers are one to two or even multiple layers. During the composite process, uniform transverse cracks appear due to different alloy shrinkage ratios, which is the remarkable feature of wear-resistant steel plate.

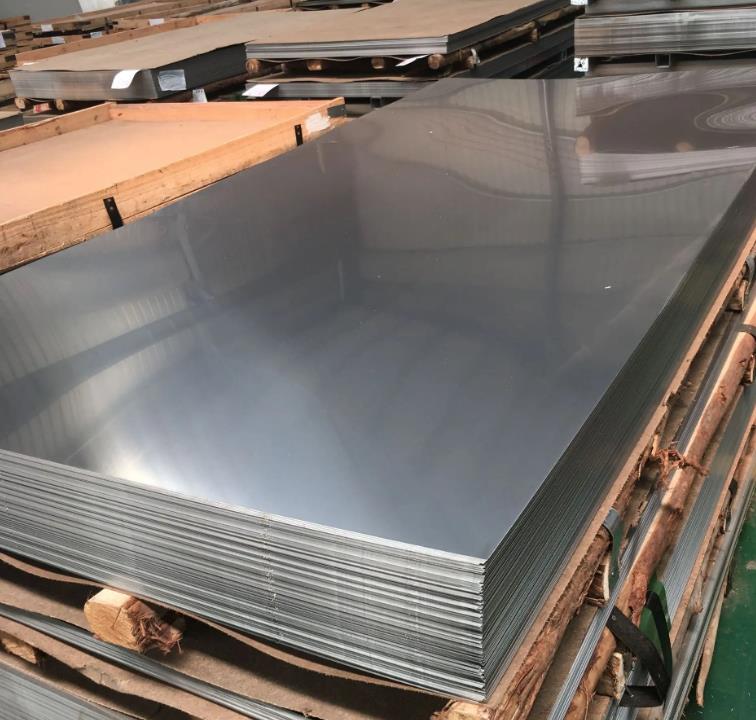

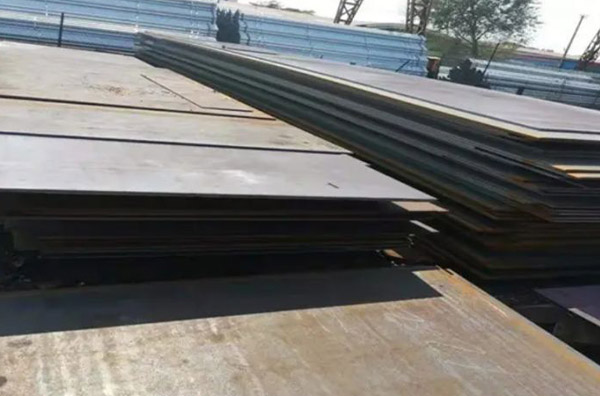

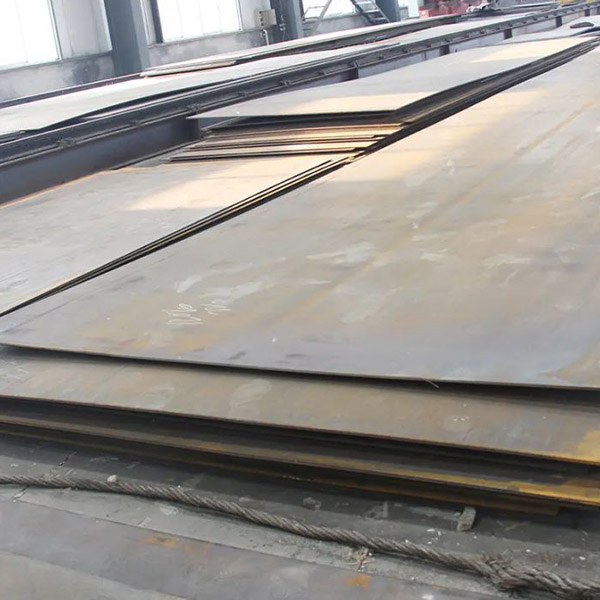

Product detail pictures:

Related Product Guide:

So that you can fulfill client's demands, all of our operations are strictly performed in line with our motto "High Excellent, Competitive Price, Fast Service" for Special Design For NM 450 Steel Plate - Theoretical Knowledge of Wear-Resistant Steel Plate – XINXIN PENGYUAN , The product will supply to all over the world, such as: Myanmar, Slovakia, Bulgaria, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!